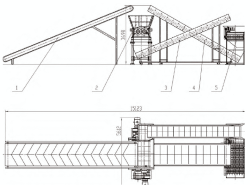

Automatic Flexographic Printing, Die-cutting Folder Binding

Vacuous adsorbing front feeding paper system, applicable to all kinds of flute profile, transfer smoothly with high speed and precise.

Use and characteristics

1. Vacuous adsorbing front feeding paper system, applicable to all kinds of flute profile.transfer smoothly;high speedly and precisely.

2. Frequency transformer devices have been adopted to use on the host, fans and phase adjustment.

3. The drive gear:20GrMnTi high frequency-quenched and carburizing done.

4. Cross-trundling roller driving system, no wear for long time using, ensure for transmission accuracy.

5. Free-keys connection style, roller connects with gear, ensure for registration accuracy

6. Blade-block can be traversed or the carton height can be adjusted, anti- collision device can ensure the safety of the machine.

7. Mechanical spray lubrication, pump circulating system for gears, make gear service life long. Auto-return function.

8. Function of storage of normal die-cutting orders, fast and efficient.

Technical parameters

| Modle | 900 | 1224 | 1424 | 1624 | |

| Max. machine speed(pcs/m) | 300 | 250 | 180 | 150 | |

| Max.feeding size(mm) | 900×2400 | 1250×2700 | 1450×2800 | 1660×2700 | |

| Min.feeding size(mm) | 280×680 | 350×680 | 360×680 | 420×680 | |

| Max.printing area(mm) | 880×2000 | 1200×2400 | 1400×2400 | 1600×2400 | |

| Max depth of slotting (mm) | 230 | 300 | 300 | 410 | |

| Die cutting size (mm) | ≤±1.5 | ||||

| Tinted precision (mm) | ≤±0.4(4 colors ) | ≤±0.5(4 colors ) | |||

| Printing plate thickness(mm) | 7.2 | ||||

| Feeding thickness (mm) | 2.5-12 | ||||

| Min.slotting interval (mm) |

Normal | 160x160x160x160 | 160x160x160x160 | 160x160x160x160 | 160x160x160x160 |

| Reverse | 300x60x300x60 | 300x60x300x60 | 300x60x300x60 | 300x60x300x60 | |

Related products

สกรูเครื่องรีดพลาสติก ขนาด SJSZ80/156

- รหัสสินค้า : สกรูเครื่องรีดพลาสติก ขนาด SJSZ80/156

- Diameter ส่วนหัว : 80 mm.

- Diameter ส่วนท้าย : 156 mm

- เหล็กที่ใช้ในการผลิต : 38CrMoAlA หรือ bimetallic ขึ้นอยู่กับความต้องการของลูกค้า

- อายุการใช้งาน : 1-3 ปี ขึ้นอยู่กับวัตถุดิบที่ใช้

สกรูเครื่องรีดพลาสติก ขนาด SJSZ65/132

- รหัสสินค้า : สกรูเครื่องรีดพลาสติก ขนาด SJSZ65/132

- Diameter ส่วนหัว : 65 mm.

- Diameter ส่วนท้าย : 132 mm

- เหล็กที่ใช้ในการผลิต : 38CrMoAlA หรือ bimetallic ขึ้นอยู่กับความต้องการของลูกค้า

- อายุการใช้งาน : 1-3 ปี ขึ้นอยู่กับวัตถุดิบที่ใช้

สกรูเครื่องรีดพลาสติก ขนาด SJSZ55/113

- รหัสสินค้า : สกรูเครื่องรีดพลาสติก ขนาด SJSZ55/113

- Diameter ส่วนหัว : 55 mm.

- Diameter ส่วนท้าย : 113 mm

- เหล็กที่ใช้ในการผลิต : 38CrMoAlA หรือ bimetallic ขึ้นอยู่กับความต้องการของลูกค้า

- อายุการใช้งาน : 1-3 ปี ขึ้นอยู่กับวัตถุดิบที่ใช้

เครื่องเสียบหมูปิ้ง

- รหัสสินค้า : เครื่องเสียบหมูปิ้ง หรือ เครื่องเสียบหมู

- ขนาด : 800*270*200mm

- จำนวนเสียบต่อครั้ง : 8 ไม้/1 ครั้ง

- กำลังการผลิต : 1000-2000 ไม้/ชั่วโมง

- น้ำหนักของสินค้า : 20 กิโลกรัม

เครื่องชิลเลอร์ Air-Chiller

- ใช้สำหรับทำให้น้ำเย็นตลอดเวลา สามารถทำได้ความเย็นได้ตั้งแต่ 5องศา-35องศา

- Cooling range : 5c~35c

- ตัวถัง Water Tank ทำมาจากสแตนเรท SUS304

- Refrigerant : R22/R410A

เครื่องบดยางหรือเครื่องรีไซเคิลยาง ( Shredder Machine )

- ใบมีดของเครื่องบดยางถูกออกแบบมาเป็นพิเศษ

- สามารถบดยางให้ได้ขนาดตามต้องการ

- สามารถบดยางได้ตั้งแต่ 1-20 ตัน/ชั่วโมง

- ขนาดเครื่องจักรจะอยู่ที่ปริมาณการบดยางต่อชั่วโมง

SJ150/33:1 SINGLE SCREW HDPE/PP/PPR/PEX/ABS EXTRUER

- Screw, Barrel : Screw and Barrel Material 38CrMoAlA,Nitriding,

- Screw Diameter :150mm

- Screw Length/Diameter Ratio : 33:1

- Main Motor Power : 320KW DC motor

- Main Motor Timing Method : Adopt British Eurotherm Inverter

- Gear box : ZLYJ315 rigid gear surface gear box

- Barrel heating : Adopt casting aluminum electrical heater, stainless steel

- cover with cooling fan(SOK)

- Heating Power : 8KW×6Zones

- Capacity : 600-1000kg/h